Pro cycling logistics: a future model for urban logistics?

13 February 2025 by Edina GÁLFI

In the food retail sector, monitoring the temperature of goods received is highly recommended if one wants to avoid a food safety scandal. This monitoring is mandatory for quick-frozen foods under Regulation (EC) No. 37/2005. It also facilitates the management of nonconformities and the taking of corrective action when needed.

Temperature monitoring guarantees and proves to the relevant authorities that the cold chain is maintained for the goods transported.

It is worth noting that every year 1,000 checks are carried out by the French authorities – specifically the Departmental Directorates for the Protection of the Population (DDPP) – on vehicles used for temperature-controlled transport. This is without counting the checks carried out by the Customs service, the police and the gendarmerie.

The food cold chain refers to all the steps in the logistics process during which perishable goods must be kept at a specific storage temperature: production, processing, warehousing/storage, transport and distribution.

There is a specific classification published by the French Agriculture Ministry which lists the regulatory storage temperatures of different categories of refrigerated and frozen foodstuffs.

For two main reasons:

For commercial reasons: to slow the process of ripening of certain types of produce. This can in fact have a non-negligible impact on the visual aspect of a foodstuff, such as its colour, but also its texture and taste. In addition, it is necessary to manage use-by dates (UBDs). The aim is to offer an optimised customer experience by extending the product’s shelf life. Refrigeration therefore guarantees and preserves the visual appearance and taste quality of temperature-sensitive foodstuffs. Perishable goods that arrive at the retail outlet at the right temperature represent a commercial guarantee for the vendor.

Food safety reasons: to slow down the deterioration of the organoleptic qualities of the product and eliminate the risk of germs and parasites developing. Refrigeration limits and slows the propagation of pathogenic microorganisms. In addition, it helps to conserve the nutritional value of foodstuffs.

Monvoisin’s Refrigeration Tripod is a model consisting of three fundamental pillars necessary to the conservation of perishable goods:

In this article we provide you with the three key factors that will enable you to successly carry out successful temperature monitoring.

An easy-to-apply method that guarantees you peace of mind.

These three tips require only good equipment, strict application of procedures and operators trained to read temperatures properly.

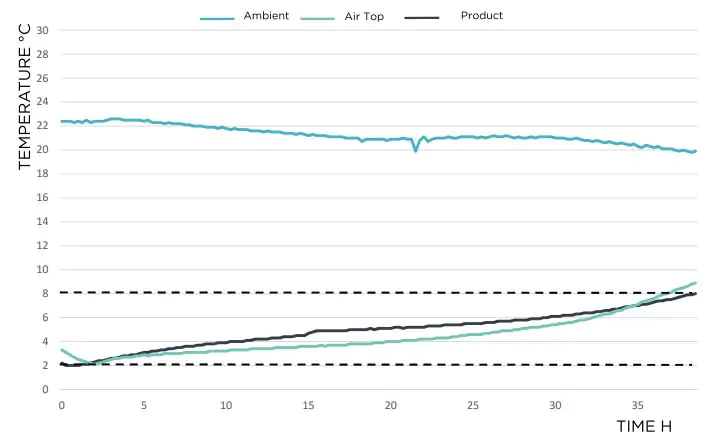

Temperatures must be monitored on final receipt at the end of the distribution chain, i.e. before they are put on display for consumers. It is necessary to be sure that the insulated container has not been opened during the different stages of its transit. Ensuring this is the case is easy: simply fit the insulated container with a data logger to record the variations in temperature inside. A sudden rise in the temperature is a good indicator that the door or lid has been opened. The temperature reading must be recorded in case of checks by the official authorities.

Avenues to explore. There are many different data loggers on the market. The NFC technology is one solution for contact-free temperature monitoring. It allows changes in the air temperature inside an insulated container to be monitored. This is done automatically and simultaneously. At Olivo we have specific systems we recommend – feel free to contact us for more information.

The second point that is particularly important concerning the scope of the checks is the contact point. In fact, a product’s temperature should be measured in contact with the packaging. The maximum difference tolerated is +/-2°C. Above that, the core temperature of the product must be measured. The maximum difference tolerated is then +/-1°C.

For example, if a yoghurt is meant to be kept at +4°C and the reading is +4.9°C, it is deemed compliant. The load will then be accepted.

Remember to provide a test product/sample of each type of foodstuff in each insulated container, i.e. on top of the quantity delivered. Because the packaging and/or packing will necessarily be damaged and the product will become unsaleable. Doing this will avoid many a pitfall.

Avenues to explore. There are many refrigeration solutions that will enable you to keep your perishable goods at the right temperature. This may be insulated containers used with eutectic plates or a cryogenic system. It is up to you to decide what your real needs are. In terms of the length of time you need to maintain the temperature, the type of products to be conserved, the infrastructure available, the quantities to be transported and the rotations. The right solution will be the one that provides you with cost-effective, efficient temperature maintenance.

Finally, temperature monitoring has to be done with officially approved equipment. Only thermometers calibrated in accordance with standards EN 13485 and EN 13486 may be used by operators. Readings taken with infrared or laser thermometers are not valid. Temperature measuring equipment must be checked on an annual basis and a calibration certificate issued to guarantee that it is working properly.

Avenues to explore. Probe-type thermometers are therefore the best tool to get accurate temperature readings. The French General Directorate for Food (DGAI) issues a list of temperature recording equipment that meets the requirements of standard EN 12830. Thermometers that meet these requirements can be recognised by their green compliance mark.