Pro cycling logistics: a future model for urban logistics?

13 February 2025 by Edina GÁLFI

15 June 2023 by Edina GÁLFI

Logista. Now there’s word that tells us something about the history of logistics. In the days of Julius Caesar, a logista was a military administrative official responsible for supplies and for setting up Roman garrisons. So logistics has its origins in the art of warfare. It really came into its own under Napoleon with Jomini, a military theoretician who introduced logistics as the management of movements: of information, troops, supplies (food, medical, military). Thanks to the deployment of this strategy of flows, war became mobile. Supply lines became a central issue.

The word Logistics, which comes from the Greek Logistikos, which also meant “skilled in calculating”. Modern logistics is therefore the art of reasoning and working out flows in order to optimise their distribution. This optimisation, today, translates into three main parameters: productivity, profitability and quality.

Following on from that, cold chain logistics consists of managing physical flows of temperature-sensitive goods. To successfully move chilled and frozen foodstuffs, it is worth looking at the factors that will contribute to successful cold chain logistics.

Choosing to extend your distribution range means rethinking the organisation and fitting out of existing infrastructure. So embarking on the distribution of chilled or frozen foodstuffs will sometimes mean acquiring equipment and addressing the different regulatory parameters specific to this type of goods. That’s all well and good, but how can you gain market share without breaking the bank and provide a quality service at the same time?

Initially, it is necessary to think about your model of flow management: pull flows or push flows? The answer to that question will tell you whether or not you need to plan to have temperature-controlled storage facilities within your warehouse.

Installing a cold room and/or a freezer room gives you more flexibility to manage orders and deal with unexpected delivery needs or issues. In some logistics configurations, a temperature-controlled chamber can also allow you to prepare your temperature-controlled delivery equipment.

Storing perishable foodstuffs is one thing. Transporting them is another and requires extra vigilance, because any break in the cold chain can have dramatic consequences: isolated cases of food poisoning or outbreaks of illness caused by bacteria like salmonella and listeria, which lead to food recalls and put lives at risk. The logistics operator or carrier can therefore be liable. The performance obligation, i.e. to keep the products transported at the right temperature, leads to an obligation of means.

Today, the fact remains that the most sustainable and flexible solution is to use a standard, i.e. non-refrigerated vehicle, combined with the use of insulated food containers that maintain the temperature of the products at +2°C/+4°C or -20°C thanks to a passive cold source. These cold sources are interchangeable to adapt to the types of foodstuffs transported.

This self-contained solution allows you to avoid the huge amounts of energy wasted in the distribution phase. Indeed, according to study conducted by Brightec, to keep chilled goods at +4°C, the opening of the doors of a refrigerated semi-trailer increases its diesel consumption by 1,125 L per year. Add to that another 4,600 L for the transport of frozen goods.

The choice of your transport solution therefore has to combine factors like the initial outlay and energy costs as well as the flexibility of use of the equipment.

The distribution of chilled and frozen foodstuffs also involves a phenomenon of seasonality which must not be neglected when considering the future development of a business. It means that the volumes transported will constantly fluctuate over the year. So a fleet of standard vehicles with insulated containers will allow you to avoid having “dormant” vehicles that you only use during peak periods. The insulated container is the answer that allows you to “pool” different temperatures. On the same standard lorry, different types of foodstuffs can be transported together: dry, chilled, frozen.

This principle of pooling therefore guarantees optimised loading patterns and delivery rounds.

Finally, the standard lorry/insulated container pair maximises return on investment since it allows you to alternate the transporting of chilled, frozen and ambient-temperature products. And in fact, the same insulated container can be used to transport, in succession, chilled or frozen foodstuffs by changing the cold source used: fresh or frozen eutectic plates or dry ice.

Defining a cold chain logistics solution for the transporting of chilled and frozen foodstuffs must be an integral part of a business development plan. This must take several factors into account:

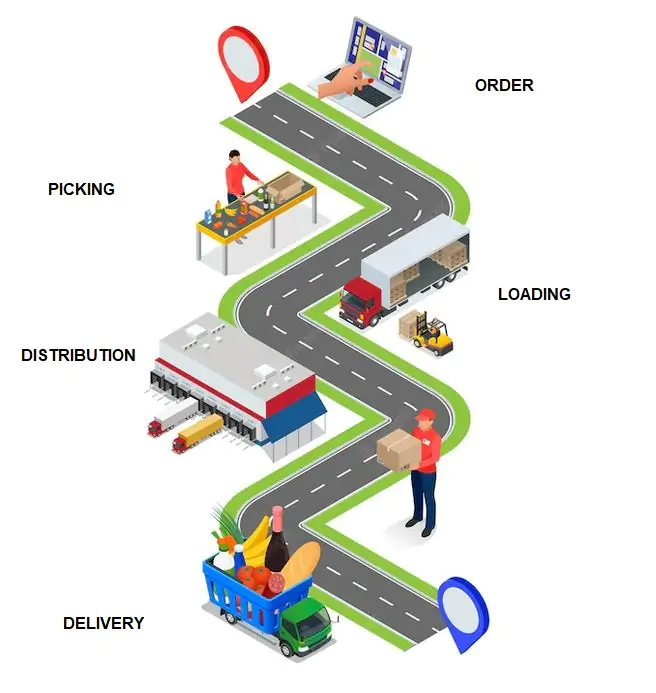

The answers to these three questions will provide some key indicators for the development of a logistics strategy; the volumes distributed, which will correspond to a well-defined composition of an average “basket”, the market places where supply and demand come together, which are specific to your business model (physical sales, online sales), the means of delivery used, to be chosen according to the environment where the flows take place (urban, peri-urban, rural) and the regulatory framework to which this mobility is subject.

Once again, the standard vehicle/insulated container pairing comes into own when there is a need to deliver chilled and frozen goods. The insulated container + passive cold source format has the advantage of adapting to any mode of transport: lorry, van, car, bike or scooter. ROLL, BOX or BAC containers of all sizes can be loaded and combined to optimise the use of the space inside the vehicle.

Choosing adaptable, flexible equipment when planning cold chain logistics is essential these days, in a period where we are seeing huge and rapid changes in modes of consumption. Easy handling, multi-purpose usage and long service life are requirements that are characteristic of solid, sustainable cold chain logistics.

Once you have defined your mode of transport and the means of controlling temperatures, you then have to think about the continuity of your cold chain in itself. Different contingency factors influence cold chain logistics for foodstuffs and the calibration of the cold source that will be necessary:

Finally, you must keep in mind the obligation of result specific to the distribution of temperature-sensitive foodstuffs. It is therefore highly recommended to set up a temperature checking system in order to guarantee the food safety of the products distributed and to be able to prove that the cold chain is not broken during the distribution phase.