Preventive maintenance for insulated containers : ensuring the success of ATP renewal

26 September 2024 by Webqam

In the food logistics industry, maintaining Olivo insulated containers is crucial for ensuring product quality and safety. Regular maintenance not only prevents early deterioration and equipment sustainability but also reduces the risk of Musculoskeletal Disorders (MSDs) among staff. Learn how to enhance your equipment’s performance through effective maintenance practices and tailored training.

How to maintain my Olivo insulated container ?

Proper management of your Olivo insulated containers relies on several key maintenance practices. Here are the essential steps to ensure their optimal functioning:

- Regular visual inspection

- Perform regular inspections to detect signs of wear or failure. Check the integrity of:

- Walls

- Seals

- Closing mechanisms

- Preventive inspections help identify issues before they impact your operations.

- Perform regular inspections to detect signs of wear or failure. Check the integrity of:

- Refrigeration system check

- Ensure the refrigeration system is functioning correctly. Verify the sealing of the eutectic plate and SIBER® trays, as well as the attachment of magnetic eyelets. For the SIBER® system, the injection totem also requires regular maintenance, including defrosting.

- Cleaning and disinfection

- Clean the interior and exterior of the containers with appropriate products to maintain high hygiene standards. Disinfection is also crucial to avoid cross-contamination.

Discover our maintenance videos for practical tips and step-by-step demonstrations.

Preventive maintenance : reducing MSDs and maximizing performance

Preventive maintenance is essential to prevent Musculoskeletal Disorders (MSDs) and ensure optimal equipment performance. Here’s how a preventive approach can help:

- Scheduling interventions

- Create a maintenance schedule for regular inspections and necessary repairs. Effective planning helps avoid unexpected breakdowns and keeps equipment in good condition.

- Create a maintenance schedule for regular inspections and necessary repairs. Effective planning helps avoid unexpected breakdowns and keeps equipment in good condition.

- Reducing ergonomic risks

- Preventive maintenance reduces emergency repairs. Use ergonomic tools to minimize physical effort and prevent injuries.

- Preventive maintenance reduces emergency repairs. Use ergonomic tools to minimize physical effort and prevent injuries.

- Performance monitoring

- Track performance indicators to detect anomalies early and adjust maintenance procedures. Regular monitoring helps prevent failures and improves equipment efficiency.

According to a study by the National Institute for Research and Safety (INRS), a preventive maintenance program can reduce MSDs by 30% and unexpected repair costs by 20%.

Team awareness and training : a key approach

Training and raising awareness among staff are crucial for effective maintenance on long term. Here’s how to enhance your team’s skills :

- Regular training sessions

- Organize training for teams on container maintenance procedures and cleaning techniques. Regular training ensures proper adherence to maintenance practices.

- Organize training for teams on container maintenance procedures and cleaning techniques. Regular training ensures proper adherence to maintenance practices.

- Documentation and guides

- Provide detailed manuals and maintenance guides to help your team follow best practices. Clear documentation facilitates procedure execution.

- Provide detailed manuals and maintenance guides to help your team follow best practices. Clear documentation facilitates procedure execution.

- Safety culture

- Foster a safety culture where risk prevention is a priority. Ensure teams report issues immediately and follow maintenance procedures rigorously.

Support your team daily in their maintenance operations

Education

Training internal teams in various handling procedures and maintenance routines.

Operations

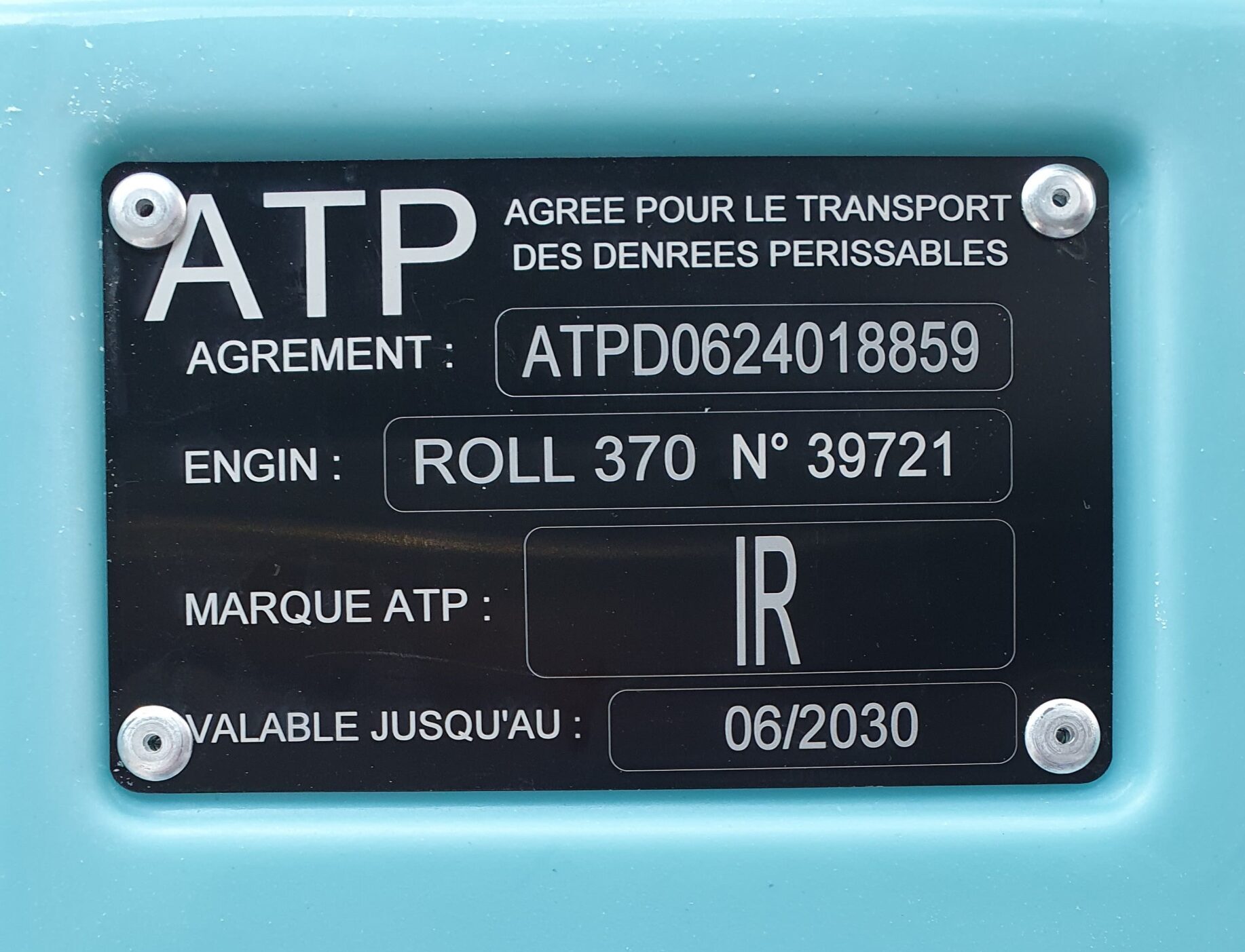

A team is deployed on-site for the inspection of your insulated containers’ fleet in compliance with the ATP standards.

Tips for regular maintenance

To optimize the maintenance of your Olivo insulated containers, consider these practical tips:

- Using specific tools

- Employ appropriate tools for cleaning and maintaining containers. Using the right tools prevents surface damage and improves maintenance efficiency.

- Temperature checks

- During use, regularly monitor the internal temperatures of containers. Ensure they stay within recommended ranges for optimal performance.

- Recording interventions

- Keep a maintenance log to track performed interventions, replaced parts, and relevant observations. This documentation helps plan future maintenance.

- Post-intervention checks

- After each intervention, conduct a full test to ensure everything functions correctly. Check seals, closing mechanisms, and the refrigeration system.

Performing preventive maintenance operations requires the implementation of an organization guided by various QHSE procedures and execution protocols. Effective maintenance involves planning and performance monitoring. It’s entirely possible to start tracking using simple tools, such as a monitoring table that includes the following informations.

| ROLL serial number | Manufacturing date | Container model | Intervention date | Actions carried out | Spare part manufacturer reference | Excl. VAT cost |

|---|---|---|---|---|---|---|

| 24009 | 01/08/2022 | ROLL900 | 24/09/2024 | Replacement of 4 fixed wheels Ø 125 | 08000317- | X€ |

Maintenance and cleaning of insulated containers : recommanded practices

Proper maintenance and cleaning are essential for Olivo insulated containers’ performance:

- Cleaning procedures

- Adopt regular cleaning procedures with products suitable for container materials. Clean all internal and external surfaces to prevent dirt buildup.

- Adopt regular cleaning procedures with products suitable for container materials. Clean all internal and external surfaces to prevent dirt buildup.

- Disinfection

- Disinfect containers after each use, especially when they’ve been in contact with sensitive food products. Follow health authority recommendations.

- Disinfect containers after each use, especially when they’ve been in contact with sensitive food products. Follow health authority recommendations.

- Complete drying

- Ensure containers are completely dry before reuse or storage. Residual moisture can lead to mold and bacteria.

- Ensure containers are completely dry before reuse or storage. Residual moisture can lead to mold and bacteria.

- Visual inspection

- Conduct a visual inspection after each cleaning to identify any anomalies. Check walls, seals, and mechanisms for potential issues.

For more details on maintaining Olivo insulated containers and to access specialized training, visit our maintenance training page and our YouTube channel.

Maintaining insulated containers is vital for ensuring their performance and food product safety. By implementing preventive maintenance practices, training your teams, and following rigorous maintenance procedures, you can extend the lifespan of your equipment and enhance your logistics operations.

Our news in cold logistics

View the blog